Redefining Resilience: Building the Future of End-to-End Supply Chain Planning

The world is changing rapidly, and nowhere is this more evident than in the way businesses manage their supply chains. From the relentless pressures of globalization and rising customer expectations to the evolving challenges of sustainability and technological disruption, the future of supply chain planning is more complex – and critical – than ever. To thrive in this environment, companies need more than just tools and systems. They need resilience. But what does supply chain resilience really mean in today’s world, and how can businesses achieve it? For many, the answer lies in embracing a new phase of supply chain management – one that we’re calling “Planning 2025.” It’s about more than just implementing the latest technology; it’s about transforming the way organizations think about and manage their supply chains to ensure long-term success.

From Planning 1.0 to Planning 2025: The Journey So Far

To understand where we are today, we need to look at where we’ve come from. The evolution of supply chain planning has been a steady march towards greater complexity and integration.

Planning 1.0 was a far cry from the sophisticated systems of today. In the 1980s and 1990s, most businesses relied on manual processes, with paper, physical plan boards, and endless phone calls driving logistics decisions. It was rudimentary and inefficient, but it worked – largely because human experts were at the center, using their knowledge to navigate a world of limited technological support.

Then came Planning 2.0, where organizations moved from manual methods to systems-based solutions. Over the past 25 years, businesses have adopted a wide array of advanced planning systems (APS), AI-powered planning solutions, and supply chain planning and optimization (SCP&O) tools. This shift has transformed supply chain management, allowing companies to optimize everything from demand forecasting to operational scheduling. Most companies now have multiple systems in place, often integrated with broader enterprise resource planning (ERP) processes or financial systems.

But while Planning 2.0 improved efficiency and brought more data-driven decision-making into supply chains, it hasn’t solved all the challenges. These critical, value-driving, solutions are often not fully owned by the business, but rather moving more towards IT ownership. And even with the technological advancements, companies are still heavily reliant on humans – on the tribal knowledge that lives in the heads of a few experts, supported by a proliferation of spreadsheets to fill the gaps between systems. Hence, companies are still grappling with complexity, siloed operations, and a growing demand for real-time, adaptive systems.

And now, in an era defined by economic uncertainty, supply chain disruptions, and an increasing focus on sustainability, it’s clear that the next phase – Planning 2025 – is upon us.

Planning 2025: The Building Blocks of Resilience

So, what does Planning 2025 look like? At its core, this new phase of supply chain management is about building resilience – having the capacity to adapt quickly to disruptions while maintaining efficiency and profitability. Represented as a formula, IDC1 views supply chain resiliency as: visibility + intelligence + agility. In the context of Planning 2025:

- Visibility: In a resilient supply chain, companies must have a clear, real-time overview of their KPIs, performance metrics, and the overall state of their supply chain. This level of visibility is essential for making informed decisions quickly, especially when disruptions occur.

- Intelligence: Supply chains today must go beyond basic data analysis. Optimization, decision support systems, and AI-powered tools provide the intelligence needed to drive effective planning on a strategic, tactical, and operational level.

- Agility: Perhaps the most important aspect of resilience is the ability to adapt quickly to changing circumstances. Whether it’s responding to a sudden shift in demand, a supply chain disruption, or regulatory changes, agility allows companies to react in real time without compromising performance.

But resilience isn’t just about having the right tools in place. Two additional building blocks – collaboration and sustainable optimization – are crucial to ensuring that businesses can weather the upcoming storms.

Collaboration: Breaking Down Silos

One of the biggest obstacles to supply chain resilience is the continued presence of silos within organizations. Despite all the technological advances of the past few decades, many companies still struggle to foster collaboration between key departments – whether that’s design, supply chain, finance, logistics, or manufacturing. Technology alone cannot solve this problem.

Take, for example, the Sales and Operations Planning (S&OP) process. In many companies, different teams – design, manufacturing, logistics – often fail to collaborate effectively, leading to inefficiencies and missed opportunities. The same holds true for trade-offs between production and logistics, or between supply chain management and executive decision-making.

In the future, successful organizations will be those that prioritize collaboration across all levels of the business. By fostering a culture of open communication and shared goals, supported by the right technology, businesses can break down silos and ensure that all parts of the organization are aligned toward common objectives. In essence, collaboration will be the “glue” that holds resilient supply chains together.

Sustainable Optimization: Balancing Profit, Efficiency, and Responsibility

The conversation around sustainability is no longer optional – it’s essential. For years, businesses have optimized their supply chains with a focus on profitability and operational efficiency. But in the age of climate change, regulatory pressure, and shifting consumer expectations, sustainability has become a third pillar of optimization.

This shift is challenging because it requires companies to make difficult trade-offs between these three often-competing goals. For example, how do you balance the need for operational excellence with the push for profitability and the imperative to reduce your environmental footprint?

Businesses are already facing this challenge head-on. One European mining company, for instance, recently operationalized a new sustainable optimization model. In their day-to-day operations, they now balance profitability with operational efficiency and sustainability goals, recognizing that their future depends on making responsible decisions today. They’re not alone in this effort – many companies across industries are beginning to adopt similar approaches, understanding that the future of their business depends on sustainable practices.

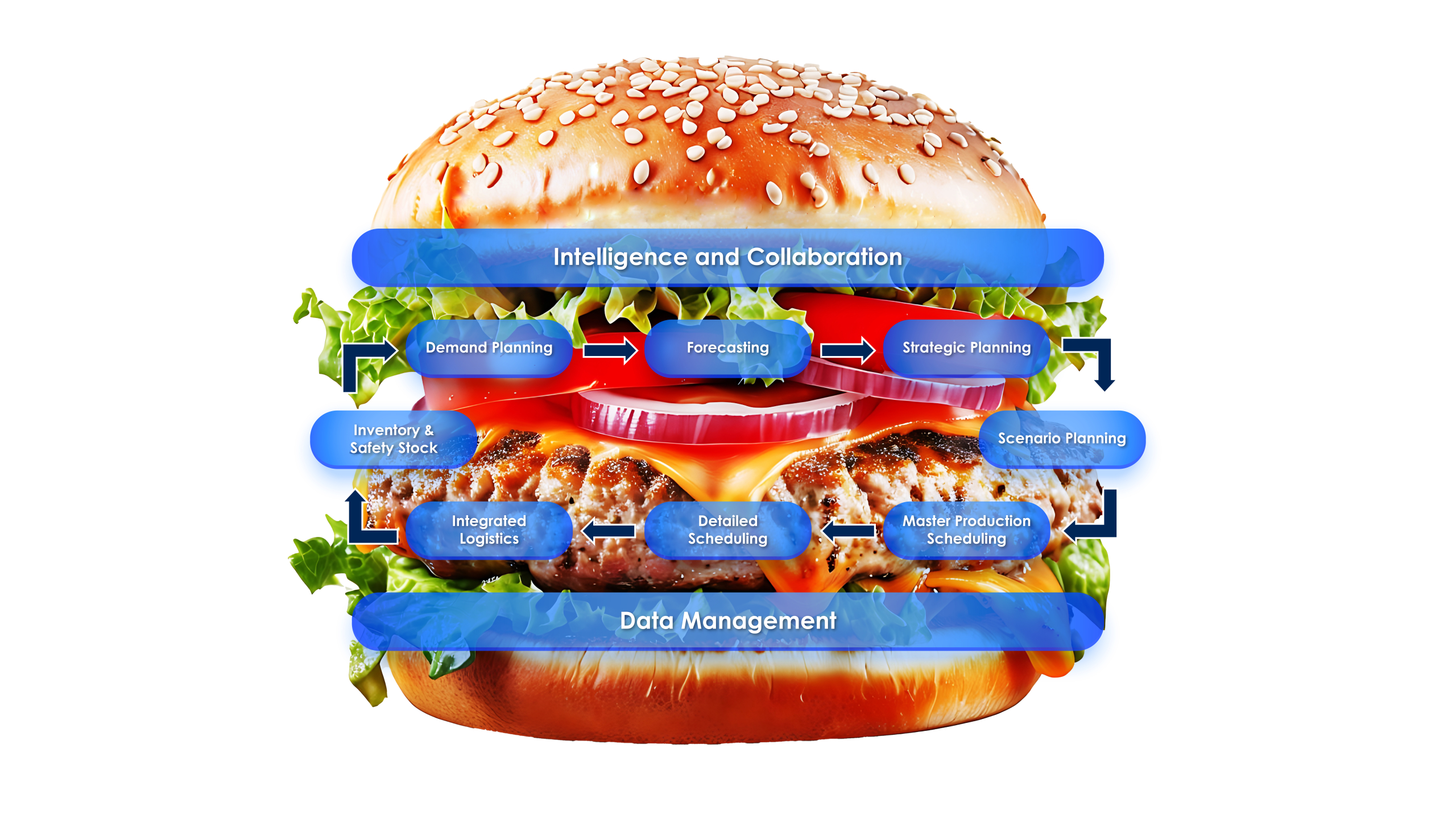

The Hamburger: A Framework for Resilience

To think about how all of these elements – technology, collaboration, and sustainability – come together, consider the analogy of a hamburger. In a resilient supply chain, the “juicy” parts are the advanced planning systems, optimization tools, and AI solutions that drive efficiency and intelligence. But without structure, these elements alone won’t lead to success.

You need the “buns” to hold everything together – not only at the end of an implementation program, but always and everywhere. At the bottom, the bun is data – and not just data availability, but data quality. As the saying goes, “garbage in, garbage out.” Without high-quality data, even the most sophisticated systems will fail to deliver meaningful insights or drive intelligent decisions.

On top, the bun is collaboration. In a truly resilient supply chain, teams across the organization must be able to work together seamlessly. This means more than just implementing systems – it requires a culture of communication, trust, and shared goals.

Preparing for the Future

As we look ahead to the next 5 to 10 years, the big question is: Are our supply chains resilient enough to withstand the challenges to come? For many companies, the answer may be no – but it doesn’t have to stay that way.

Achieving resilience requires a shift in mindset. It’s not just about implementing the latest technology or optimizing for profitability; it’s about creating a supply chain that can adapt, collaborate, and make decisions that balance efficiency, profitability, and sustainability.

There is no magic wand for building resilience. It takes vision and commitment from senior management, investment in high-quality data and systems, and, perhaps most importantly, a focus on the people who will drive these changes forward. At the end of the day, businesses are run by people – and those people need the right tools, training, and support to ensure the resilience of their organizations. The future is uncertain, but one thing is clear: Resilient supply chains will be the key to success in the years to come.

We understand that businesses are focused on one thing: winning. No one embarks on a journey for a mere technical implementation – systems alone don’t drive success. To achieve significant value that translates into measurable strategic goals or financial gains, you need real business transformation. And for that, you need more than just technology. At The Logic Factory, we see ourselves as your pit crew – the team working behind the scenes to ensure you, the driver, have everything you need to win the race. Your car – the cutting-edge technology that powers your supply chain – is critical, but without the right strategy, support, and execution, it won’t get you across the finish line. As your pit crew, our role is to ensure that your vision is aligned with your systems, your data is reliable, and your team is prepared for success. In short, we’re here to ensure that your journey ends where it should: crossing the finish line as a winner.

Interested in learning how these strategies can drive your business forward? Let’s start a conversation!

This is Part 1 in a series of 4 articles: click here for:

Part 2: Sustainable Optimization: Balancing Profit, Efficiency, and Environmental Responsibility

Part 3: Building Resilience with the Hamburger Framework: Data and Collaboration as the Foundation

Part 4: Why Sustainable Optimization and The Hamburger Framework are the Future of Supply Chain Success

References

1IDC MaturityScape: Digital Supply Chain Resiliency 2.0, Eric Thompson, May 2024.