Building Resilience with the Hamburger Framework: Data and Collaboration as the Foundation

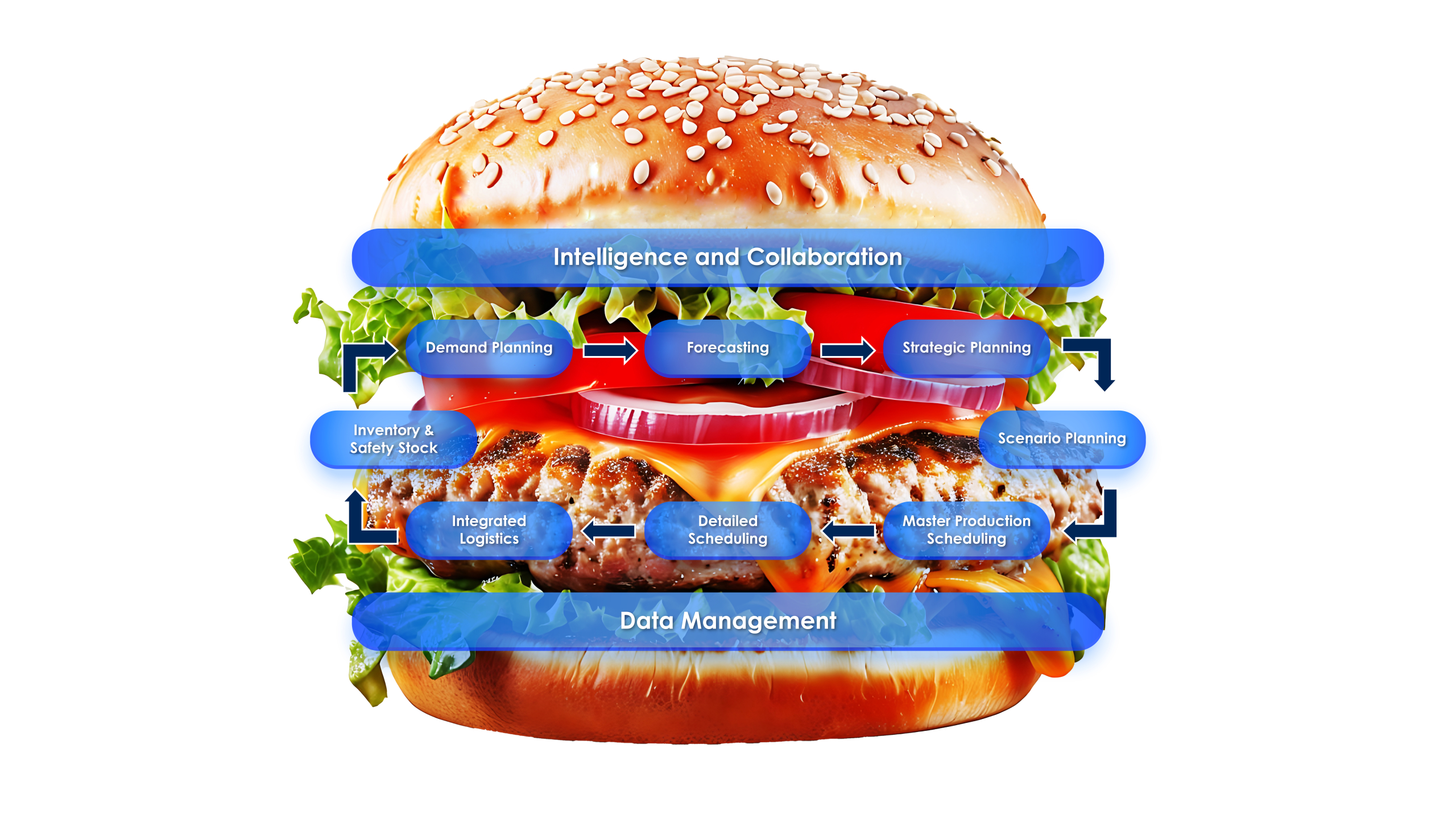

In our first article, we introduced the concept of Planning 2025 as a way to rethink supply chain planning for the future. At the heart of this framework is a simple but powerful analogy: the Hamburger. Like any great burger, a resilient supply chain has delicious ingredients in the middle – advanced technologies, optimization tools, and AI solutions. But those juicy parts won’t hold together without the critical structural elements, the buns: data and collaboration.

The “Hamburger” analogy highlights that it’s not enough to have the best systems in place; the success of your supply chain rests on two essential building blocks. Let’s dive deeper into why data and collaboration are the foundation of supply chain resilience.

The Bottom Bun: Data Quality and Availability

A juicy hamburger may look appetizing, but without a solid base, it won’t stand a chance. In supply chains, the bottom bun is data – and not just data quantity, but data quality. For years, companies have collected massive amounts of information across their operations, but as any planner will tell you, “Garbage in, garbage out.” Bad data undermines even the most sophisticated optimization efforts.

Today, supply chains operate in an era of “big data,” and while we now have data lakes and real-time analytics, the true challenge lies in ensuring that this data is reliable, accessible, and structured. When different departments or business units collect data independently, the result can be chaotic. For resilience, companies need a centralized approach to data management, one that is continuously monitored for quality.

Good data fuels visibility and provides the intelligence required for good decision-making, allowing you to forecast more accurately, respond to disruptions faster, and optimize your operations more effectively. Simply put, without a solid data foundation, your supply chain planning efforts won’t have the support you need to thrive in a fast-changing world.

The Big Data Paradox

However, many companies fall into the trap of thinking that more data equals better decisions. The reality is that unless your data is clean, organized, and appropriately leveraged, it can create more confusion than clarity. This is why businesses must focus not just on collecting data but on managing it. This is where intelligence comes in – ensuring the right people get the right information at the right time.

A key takeaway? The bottom bun of your supply chain hamburger – data – needs to be rock solid. That means identifying gaps, identifying the illogical parts, and having the ability to enrich or fix it. Without that, even the most advanced planning systems will crumble under pressure.

The Top Bun: Collaboration Across Teams

The top bun in the Hamburger analogy is collaboration. In most organizations, supply chain management is an intricate dance involving multiple stakeholders – from logistics to production, finance to customer service. For many, the biggest obstacle to supply chain resilience isn’t technology – it’s a lack of collaboration between these various teams.

This siloed approach to planning leads to inefficiencies, miscommunication, and missed opportunities. Take, for example, the classic disconnect in Sales and Operations Planning (S&OP). While S&OP processes are designed to align supply with demand, in practice, many companies find that these teams struggle to work together efficiently. The result? Forecasting inaccuracies, delayed responses, and frustrated teams.

A resilient supply chain demands cross-functional collaboration, from design to supply chain, from planning to shopfloor execution. Teams need to be aligned not just on data and metrics but on goals, expectations, and timelines. Communication must flow seamlessly across departments to ensure that any disruption – whether a demand spike or a logistics bottleneck – can be addressed quickly and effectively.

Bringing It All Together: The Power of Data and Collaboration

The synergy between data and collaboration can transform a good supply chain into a resilient one. High-quality data provides the intelligence and insights that enable teams to make informed decisions, while collaboration ensures that these decisions are implemented effectively. In a world where disruptions are becoming the norm, companies can no longer afford to rely on fragmented operations and disconnected data.

The Hamburger Framework reminds us that while the middle layers – technologies, advanced planning systems, and optimization – are essential, they won’t hold together without the buns: strong data and cohesive collaboration. These are the two ingredients that turn supply chains into resilient, adaptable operations capable of responding to whatever comes next.

We understand that businesses are focused on one thing: winning. No one embarks on a journey for a mere technical implementation – systems alone don’t drive success. To achieve significant value that translates into measurable strategic goals or financial gains, you need real business transformation. And for that, you need more than just technology. At The Logic Factory, we see ourselves as your pit crew – the team working behind the scenes to ensure you, the driver, have everything you need to win the race. Your car – the cutting-edge technology that powers your supply chain – is critical, but without the right strategy, support, and execution, it won’t get you across the finish line. As your pit crew, our role is to ensure that your vision is aligned with your systems, your data is reliable, and your team is prepared for success. In short, we’re here to ensure that your journey ends where it should: crossing the finish line as a winner.

Interested in learning how these strategies can drive your business forward? Let’s start a conversation!

This is Part 3 in a series of 4 articles: click here for:

Part 1: Redefining Resilience: Building the Future of End-to-End Supply Chain Planning

Part 2: Sustainable Optimization: Balancing Profit, Efficiency, and Environmental Responsibility

Part 4: Why Sustainable Optimization and The Hamburger Framework are the Future of Supply Chain Success